玉米片设备,玉米片生产线 美式玉米片详细报价单

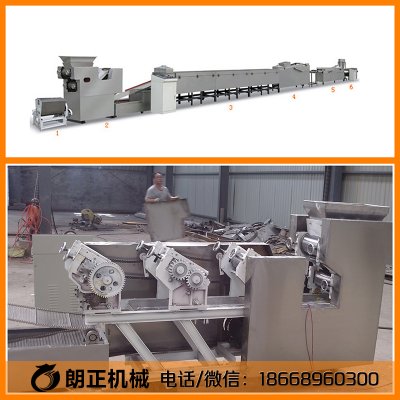

一、设备图片/Equipment pictures:

二、设备详细介绍/Details of equipment:

本该生产线是从配料、蒸煮、压片、干燥、膨化一次完成,自动化程度高。

三、设备参数/Device parameters:

四、样品图片/Sample Pictures:

五、单机详细介绍:

七、结束语/Conclusion:

首先十分感谢你能选择咨询我们公司产品,我们公司是一家集科、工、贸为一体的高新技术企业,致力于玉米膨化机、膨化休闲食品设备、组织蛋白设备、意大利面/通心粉设备、宠物食品设备及营养大米设备等的开发、研制、生产和销售。拥有经验丰富的经营管理人员,优秀的开发设计工程师及训练有素的技术人员。

同样十分希望能够和贵公司就设备问题达成一致,祝贵公司日进斗金,生意兴隆。

二、设备详细介绍/Details of equipment:

本该生产线是从配料、蒸煮、压片、干燥、膨化一次完成,自动化程度高。

三、设备参数/Device parameters:

| 主机型号/Host Model | LZ70-II | LZ85-II |

| 电源电压/Power supply voltage | 380V/HZ | 380V/HZ |

| 装机功率/Installed power | 159KW | 189KW |

| 实耗功率/Actual power consumption | 107KW | 135KW |

| 生产能力/Production capacity | 180-220Kg/h | 300-500Kg/h |

| 生产线长/Production lines long | 50m | 50m |

| 价格(元)/Price (RMB) | 593000 | 645000 |

| 增值税发票(元)/VAT invoice price (RMB) | 652300 | 709500 |

| 到港价(元)/FOB (RMB) | 670000 | 729500 |

四、样品图片/Sample Pictures:

五、单机详细介绍:

| 设备名称/Device Name | 拌粉机/Mixer | |

| 型号/Model | BFJ-II | |

| 设备参数/Device parameters | ||

| 电源电压/Power supply voltage | 380V/50HZ | |

| 装机功率/Installed power | 4KW | |

| 实耗功率/Actual power consumption | 4KW | |

| 生产能力/Production capacity | 20-40Kg/次(Time) | |

| 尺寸大小/Size | 1×0.6×1.1m | |

| 设备简介/Equipment Introduction | ||

|

混合原料、辅料和水等物料,速度适中、混合均匀。 Mixing raw materials, supplies, and water, moderate speed, and mix well. |

||

| 设备名称/Device Name | 螺旋提升机/Screw hoister | |

| 型号/Model | LST-II | |

| 设备参数/Device parameters | ||

| 电源电压/Power supply voltage | 380V/50HZ | |

| 装机功率/Installed power | 1.5KW | |

| 实耗功率/Actual power consumption | 1.5KW | |

| 生产能力/Production capacity | 80-500Kg/次 | |

| 尺寸大小/Size | 1.5×0.7×2.5m | |

| 设备简介/Equipment Introduction | ||

|

利用螺旋机构把原料提升到喂料机中。 Screw mechanism to enhance the raw material to the feeder. |

||

| 设备名称/ Device Name | 双螺杆膨化机/ Twin-screw extruder | ||

| 型号/Model | LZ70-II | ||

| 设备参数/ Device parameters | |||

| 电源电压/Power supply voltage | 380V/50HZ | ||

| 装机功率/Installed power | 46KW | ||

| 实耗功率/Actual power consumption | 30-46KW | ||

| 生产能力/Production capacity | 180-220Kg/h | ||

| 尺寸大小/Size | 3.6×1.0×2m | ||

| 设备简介/Equipment Introduction | |||

|

该机由供料系统、挤压系统、旋切系统、加热系统、传动系统、控制系统组成。采用先进的螺杆挤压膨化技术,利用高温高压将物料熟化并膨化成型,一次性完成。主机采用变频调速,保证生产过程的稳定性。产品花色、品种多样、外表美观、自然逼真、质感细腻、原料使用广泛。 Machine consists of feeding system, extruding system, peeling systems, heating system, transmission system, control system. Advanced screw extrusion technology, the use of high temperature and pressure curing and extrusion molding the material, once completed. Host with frequency control, to ensure the stability of the production process. Product color, species diversity, looks beautiful, natural and realistic, delicate texture, materials widely used. |

|||

| 设备名称/ Device Name | 冷却输送机/Cooling machine | ||

| 型号/Model | LSJ-II | ||

| 设备参数/ Device parameters | |||

| 电源电压/Power supply voltage | 380V/50HZ | ||

| 装机功率/Installed power | 1.5KW | ||

| 实耗功率/Actual power consumption | 1.5KW | ||

| 生产能力/Production capacity | 80-500 Kg/h | ||

| 尺寸大小/Size | 0.6×0.5×0.5m | ||

| 设备简介/Equipment Introduction | |||

|

用于初步冷却风干产品。 Used for preliminary cooling air-dried. |

|||

| 设备名称/Device Name | 风送机 | ||

| 型号/Model | FSJ-II | ||

| 设备参数/Device parameters | |||

| 电源电压/Power supply voltage | 380V/50HZ | ||

| 装机功率/Installed power | 0.55KW | ||

| 实耗功率/Actual power consumption | 0.55KW | ||

| 生产能力/Production capacity | 80-500Kg/h | ||

| 尺寸大小/Size | 1.2×0.6×2.3m | ||

| 设备简介/Equipment Introduction | |||

|

用于把膨化食品输送到下一个设备中。 The puffed food for delivery to the next device |

|||

| 设备名称/Device Name | 压片机/Flaking machine | |

| 型号/Model | YPJ-II | |

| 设备参数/Device parameters | ||

| 电源电压/Power supply voltage | 380V/50HZ | |

| 装机功率/Installed power | 11KW | |

| 实耗功率/Actual power consumption | 8-11KW | |

| 生产能力/Production capacity | 150-500Kg/h | |

| 尺寸大小/Size | 1.5×0.8×0.8m | |

| 设备简介/Equipment Introduction | ||

|

用于将半成品压成片状产品。 For semi-finished pressed into a sheet product. |

||

| 设备名称/Device Name | 风送机 | ||

| 型号/Model | FSJ-II | ||

| 设备参数/Device parameters | |||

| 电源电压/Power supply voltage | 380V/50HZ | ||

| 装机功率/Installed power | 0.55KW | ||

| 实耗功率/Actual power consumption | 0.55KW | ||

| 生产能力/Production capacity | 80-500Kg/h | ||

| 尺寸大小/Size | 1.2×0.6×2.3m | ||

| 设备简介/Equipment Introduction | |||

|

用于把膨化食品输送到下一个设备中。 The puffed food for delivery to the next device |

|||

| 设备名称/Device Name | 烤箱/Oven | |

| 型号/Model | KX5-II | |

| 设备参数/ Device parameters | ||

| 电源电压/Power supply voltage | 380V/50HZ | |

| 装机功率/Installed power | 36.75KW | |

| 实耗功率/Actual power consumption | 26-36.75KW | |

| 生产能力/Production capacity | 180-500Kg/h | |

| 尺寸大小/Size | 5.1×1.2×2.1m | |

| 设备简介/Equipment Introduction | ||

|

用于把生产出来的半成品产品进行干燥脱水,采用带式干燥装置,烤箱内装置一定数量的加热装置,利用电力加热进行干燥。为膨化产品最常用的干燥脱水装置。 Produced semi-finished products for dry and dehydrated with drying device,a certain amount of heating device installed inside the oven , use of electric heating to dry . The most commonly used for extruded products desiccation device. |

||

| 设备名称/ Device Name | 提升机/Hoister | |

| 型号/Model | BLT-II | |

| 设备参数/ Device parameters | ||

| 电源电压/Power supply voltage | 380V/50HZ | |

| 装机功率/Installed power | 0.75KW | |

| 实耗功率/Actual power consumption | 0.75KW | |

| 生产能力/Production capacity | 100-260Kg/h | |

| 尺寸大小/Size | 1.8×0.6×2.3m | |

| 设备简介/Equipment Introduction | ||

|

用于提升产品到烤箱 Used to enhance the product to reach the oven. |

||

| 设备名称/ Device Name | 振动筛/ Distributing device | ||

| 型号/Model | ZDS-II | ||

| 设备参数/ Device parameters | |||

| 电源电压/Power supply voltage | 380V/50HZ | ||

| 装机功率/Installed power | 1.5KW | ||

| 实耗功率/Actual power consumption | 1.5KW | ||

| 生产能力/Production capacity | 80-500Kg/h | ||

| 尺寸大小/Size | 1.5×0.8×1.6m | ||

| 设备简介/Equipment Introduction | |||

|

用于把上一个设备出来的产品平均分布到下一个设备。 A device used to come out on the average distribution of the product to the next device. |

|||

| 设备名称/Device Name | 烤箱/Oven | |

| 型号/Model | KXG-II | |

| 设备参数/ Device parameters | ||

| 电源电压/Power supply voltage | 380V/50HZ | |

| 装机功率/Installed power | 36.75KW | |

| 实耗功率/Actual power consumption | 26-36.75KW | |

| 生产能力/Production capacity | 180-500Kg/h | |

| 尺寸大小/Size | 5.1×1.2×2.1m | |

| 设备简介/Equipment Introduction | ||

|

用于把生产出来的半成品产品进行干燥脱水,采用带式干燥装置,烤箱内装置一定数量的加热装置,利用电力加热进行干燥。为膨化产品最常用的干燥脱水装置。 Produced semi-finished products for dry and dehydrated with drying device,a certain amount of heating device installed inside the oven , use of electric heating to dry . The most commonly used for extruded products desiccation device. |

||

| 设备名称/ Device Name | 喷糖机/Seasoning Line | |

| 型号/Model | TTJ-II | |

| 设备参数/ Device parameters | ||

| 电源电压/Power supply voltage | 380V/50HZ | |

| 装机功率/Installed power | 5.6KW | |

| 实耗功率/Actual power consumption | 4-5.6KW | |

| 生产能力/Production capacity | 80-500Kg/h | |

| 尺寸大小/Size | 5.5×0.75×1.95m | |

| 设备简介/Equipment Introduction | ||

|

用于调节产品口味,前节滚筒用于调味,后节滚筒用于喷油,这样调味和喷油分开操作,产品的调味质量提高不少。 Used to adjust the product taste , in the previous section drum for seasoning after section roller is used to separate injection, seasoning and injection operations , and the seasoning to improve the quality of many. |

||

| 设备名称/ Device Name | 振动筛/ Distributing device | ||

| 型号/Model | ZDS-III | ||

| 设备参数/ Device parameters | |||

| 电源电压/Power supply voltage | 380V/50HZ | ||

| 装机功率/Installed power | 1.5KW | ||

| 实耗功率/Actual power consumption | 1.5KW | ||

| 生产能力/Production capacity | 80-500Kg/h | ||

| 尺寸大小/Size | 1.5×0.8×0.8m | ||

| 设备简介/Equipment Introduction | |||

|

用于把上一个设备出来的产品平均分布到下一个设备。 A device used to come out on the average distribution of the product to the next device. |

|||

| 设备名称/Device Name | 烤箱/Oven | |

| 型号/Model | KX8-II | |

| 设备参数/ Device parameters | ||

| 电源电压/Input Voltage | 380V/50HZ | |

| 装机功率/Installed Capacity | 36.75KW | |

| 实耗功率/Power Consumption | 26-36.75KW | |

| 烘干能力/Output | 180-500Kg/h | |

| 尺寸大小/Size | 5.1×1.2×2.1m | |

| 设备简介/Equipment Introduction | ||

|

用于把生产出来的半成品产品进行干燥脱水,采用带式干燥装置,烤箱内装置一定数量的加热装置,利用电力加热进行干燥。为膨化产品最常用的干燥脱水装置。 Produced semi-finished products for dry and dehydrated with drying device,a certain amount of heating device installed inside the oven , use of electric heating to dry . The most commonly used for extruded products desiccation device. |

||

| 设备名称/ Device Name | 冷却输送机/Cooling machine | ||

| 型号/Model | LSJ-II | ||

| 设备参数/ Device parameters | |||

| 电源电压/Power supply voltage | 380V/50HZ | ||

| 装机功率/Installed power | 1.5KW | ||

| 实耗功率/Actual power consumption | 1.5KW | ||

| 生产能力/Production capacity | 80-500 Kg/h | ||

| 尺寸大小/Size | 0.6×0.5×0.5m | ||

| 设备简介/Equipment Introduction | |||

|

用于初步冷却风干产品。 Used for preliminary cooling air-dried. |

|||

七、结束语/Conclusion:

首先十分感谢你能选择咨询我们公司产品,我们公司是一家集科、工、贸为一体的高新技术企业,致力于玉米膨化机、膨化休闲食品设备、组织蛋白设备、意大利面/通心粉设备、宠物食品设备及营养大米设备等的开发、研制、生产和销售。拥有经验丰富的经营管理人员,优秀的开发设计工程师及训练有素的技术人员。

同样十分希望能够和贵公司就设备问题达成一致,祝贵公司日进斗金,生意兴隆。

最新资讯

- 饼干设备行业的不断创新促进了饼干行业的发展

- 方便面设备的结构特点

- 连续油炸机如何选购

- 连续油炸机温度如何有效的控制

- 连续油炸机的使用方法

- 朗正牌连续油炸机技术上的优势

- 朗正牌连续油炸机技术上的优势

- 方便面设备五大创新点

- 方便面设备的日常保养和维护

- 剖析我国的方便面的职业现状及将来发展方向